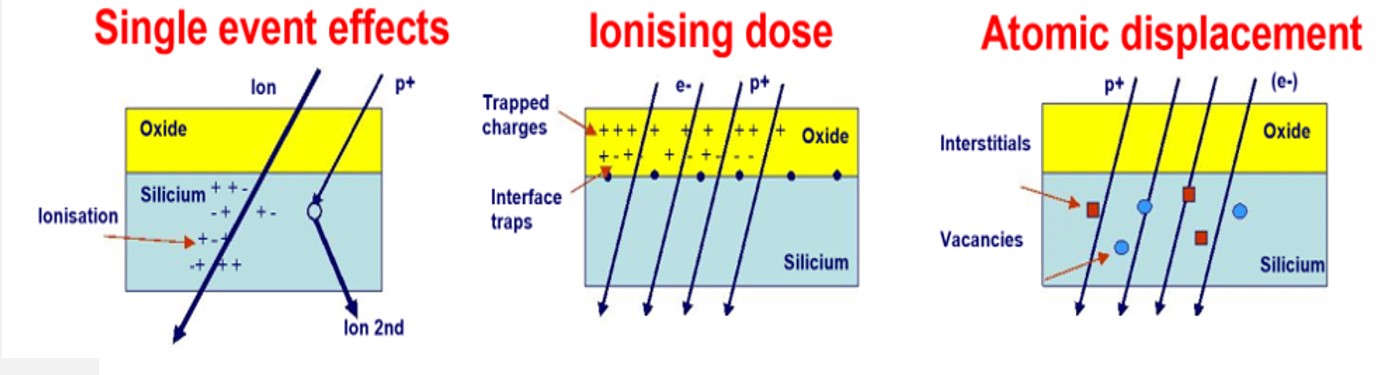

Electronic components and systems can be subjected during their use to various radiative environments rich in particles such as protons, electrons and heavy ions.

The type of particles present depends on the environment.

The space environment, for example, is rich in ionizing particles (heavy ions, protons, etc.), which is not the case for the terrestrial envenomment with the predominance of neutrons.

Both natural and man-made radiation are nowadays considered to be among the major causes of failures in high reliability electronics. The passage of a single particle can cause permanent or transient dysfunctions that can induce a loss of functionality.

For more than 15 years, we have offered solutions to guide you in the choice and use of your systems and devices in severe radiative environments with high reliability requirements.

Our tests are adapted to natural and artificial radiative constraints

Our ASER activity consists of engineers experienced in SER testing, FPGA design and high speed cards.

We have high-performance equipment for dedicated and fully personalized tests, based on a flexible and generic test platform that allows us to meet the needs of the following markets :

We collaborate with the main players in the space sector, manufacturers, agencies and laboratories for a qualification based on reference standards (MIL, ESA, JEDEC)

EES sensitivity assessment:

– Tests for heavy ions, protons

– Assessment of dose resistance

– Co60 test at different dose levels

We support the main customers to analyze the failure rate of critical components on electronic boards

EES sensitivity assessment:

– Neutron ion tests

atmospheric

– Tests in accordance with JEDEC, JESD standards

We support the players for the qualification / choice of components and the expertise to analyze the failure rate on electronic boards

EES sensitivity assessment:

– Thermal, mono-energetic and atmospheric neutron tests

– Assessment of dose resistance

– Co60 test at different dose levels

– Tests in accordance with MIL and ESA ESCC standards

Requirements specifications

Hw / Sw development of the bench

Realization of radiative campaigns

Results analysis and reporting

Thanks to more than 100 tested references, Analog and digital IPs such as: Processor ARM M, R & A, SparcV8, Q or IQ, Memories: S / D SRAM, ROM, Fuse, Flip Flops, High speed clock, IOs, High speed clock (> 5GHz), SerDes (> 15GHz), …

On BULK or FDSOI type ASIC technologies, on 130nm, 90nm, 65nm, 28nm, 22nm, 12nm and 7 nm nodes

EASii IC offers adaptive and generic test solutions allowing a significant reduction in costs and design time.

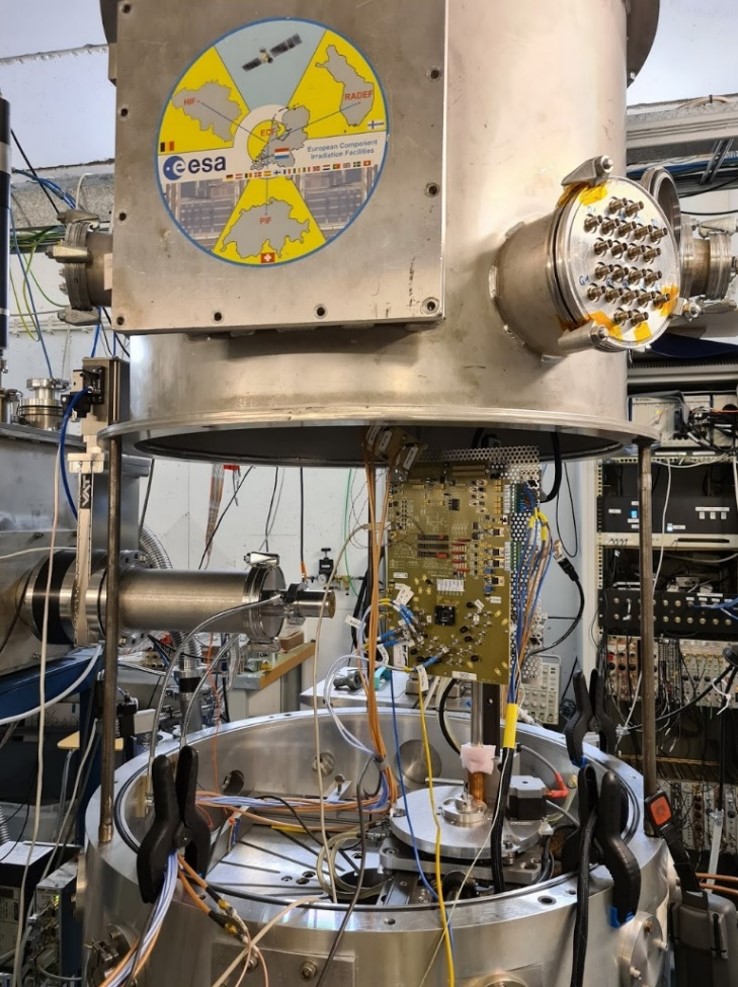

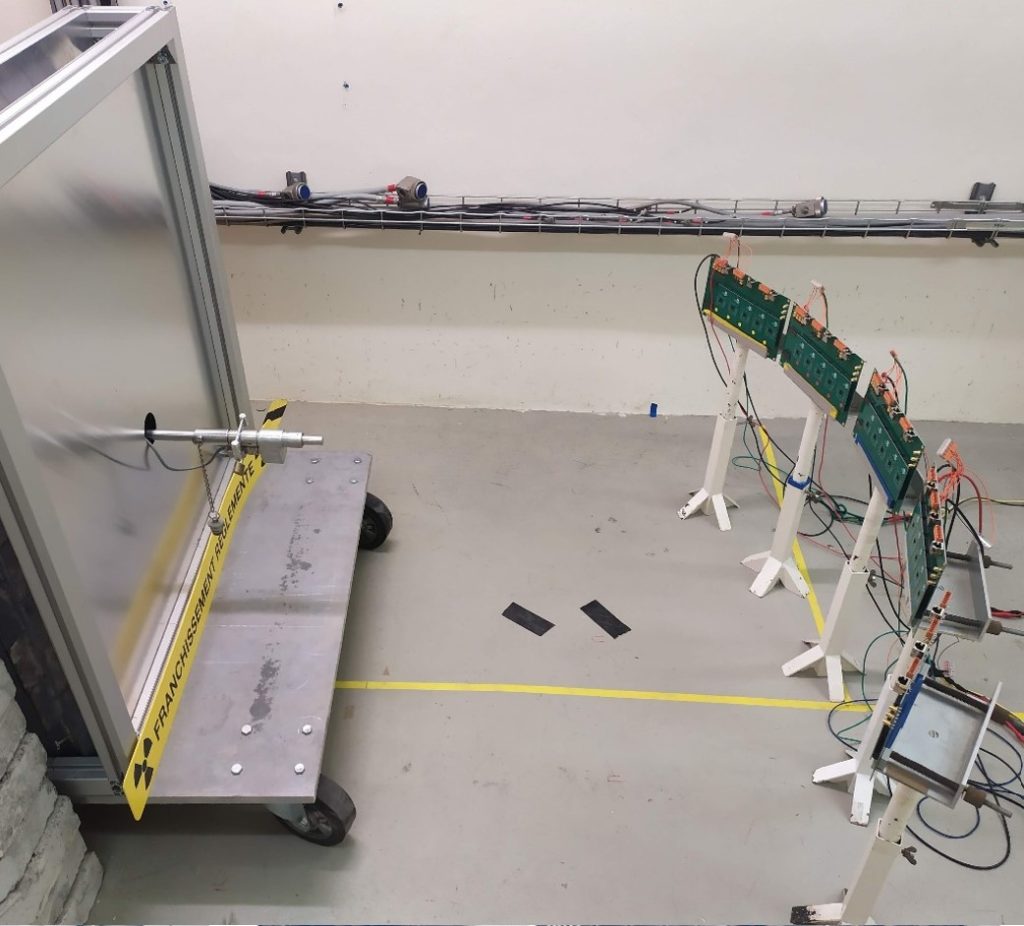

Our test benches are validated and used throughout the world in various generators and particle accelerators.

They are suitable for TID (Total Ionizing Dose) and SEE (Single Event Effect) tests and can be used in different types of radiative environments (neutrons, heavy ions, gamma radiation, alpha particles, etc.)

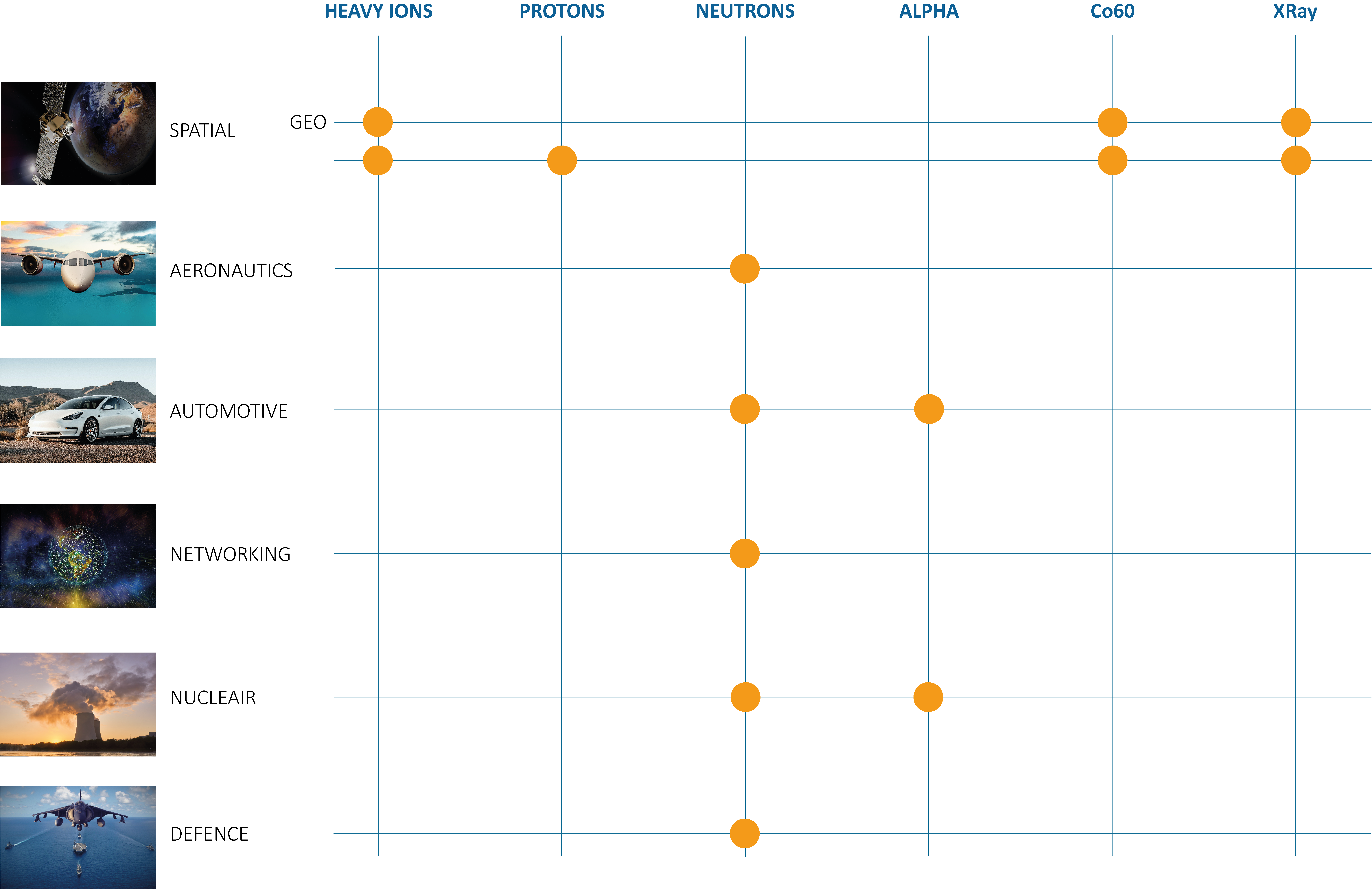

The sensitivity of electronic components and systems must therefore be evaluated according to the constraints imposed on each type of application.

We offer solutions to guide you by offering tests dedicated to your applications, as shown in the following figure:

TID tests: Evaluation of the effect of the cumulative dose on the drift of electrical and functional parameters using dedicated measurement vouchers.

Measurements are carried out at different dose steps according to the reference standards.

The SEU test consists of carrying out tests under a particle accelerator and measuring their sensitivity to events including: Single Event Upset (MBU, MCU), SET (Single Event Transient), SEL (Single Event Latch up), SEFI (Single Event Functional Interrupt) and any other so-called “singular” effect.

We have developed a platform with 256 components tested in parallel in real time.

When the platform was installed it was the 1st Real Time Test Platform at European level